Upgrade of 10 operating rooms and cleanroom buffer areas of the Alrijne Hospital location Leiderdorp.

The Alrijne Hospital is part of Alrijne Zorggroep, which also includes the nursing homes Leythenrode and Oudshoorn. Alrijne Zorggroep has over 3700 employees. The Alrijne Hospital employs 252 medical specialists and has 497 beds, distributed over the three hospital locations in Leiden, Leiderdorp and Alphen aan den Rijn. Kropman Contamination Control renovates 10 operating rooms including the cleanroom buffer areas for the Alrijne hospital location Leiderdorp.

Upgrade

The current operating rooms in the Alrijne hospital location Leiderdorp were due for an upgrade, after years of intensive use. Because of COVID-19 there was a reduction in regular care and OR capacity. Kropman Contamination Control was asked to take advantage of this quieter period and to renovate the operation rooms and cleanroom buffer areas.

In addition, issues such as sustainability and energy savings are high on the hospital's agenda. This applies not only to the operating rooms, but also to the entire hospital. In addition to saving energy, improving quality is always a wish of the hospital. This includes protecting patients and employees as best as possible from infections.

Improving quality and saving energy

At Kropman Contamination Control we advise and help all our clients to improve quality and save energy. For the Alrijne Hospital Leiderdorp, we looked for a renovation plan that would disrupt daily operations as little as possible. The quality improvement was carried out in several disciplines. First, all lighting in the operating rooms and isolation rooms replaced by LED lighting, this saves energy and provides a higher light output. On average lighting in a hospital is responsible for no less than 40% of energy costs. Adhesive seams are checked and resealed so that no unfiltered air can enter the operating area. We also replaced the HEPA filters with energy-efficient membrane filters (PTFE/teflon) that combine maximum filtration with low resistance (energy consumption). The ventilation requirement (electric fans) of an average hospital is equal to about 35% of a hospital. Finally, edge-shielding flaps are installed around the blow-in plenum in the operating room that reinforces the airflow creating a larger protected area.

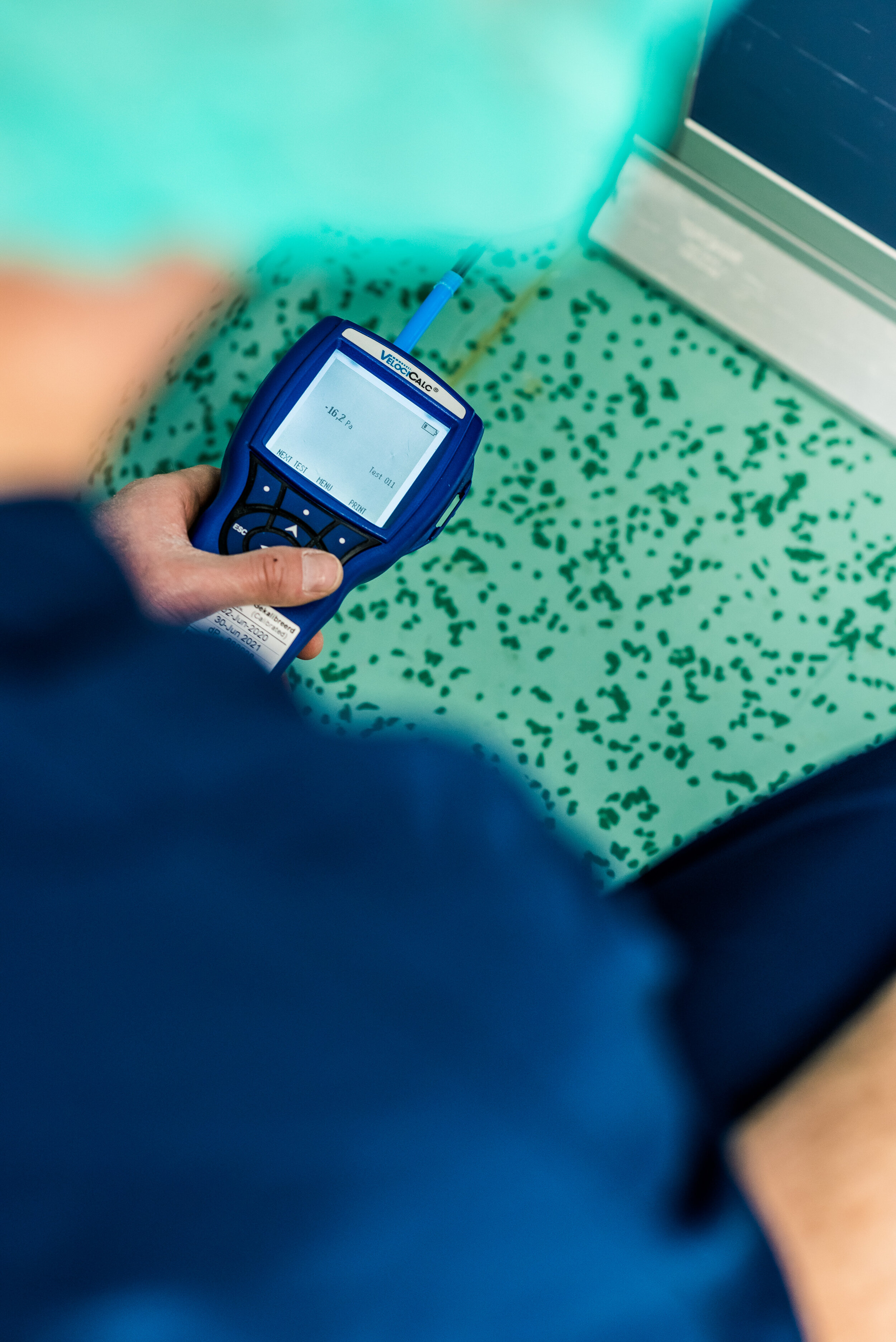

The operating rooms and buffer areas are delivered by means of qualification measurements. This shows whether the rooms meet the requirements. The following measurements were carried out:

Critical parameters: Air quantity and air velocity measurements of the down flow, determination of circulation rate, integrity test of and pressure difference measurement over the installed HEPA filters, pressure difference measurement of the surrounding areas including air flow determination, temperature and relative humidity measurements.

Performance parameters in accordance with RL-7: classification in accordance with performance level 1, particle measurements to determine dust classification, recovery time measurement to determine purge capacity, determination of protection degree to determine the size of the protected area.